Top quality of security substrates & printing

Security papers, security films, security elements and security printing must adhere to rigorous quality standards for perfect counterfeit protection. Sub-standard quality and defects result in costly complaints and rejects. Therefore, compromising manufacturing precision significantly reduces productivity and revenue.

Learn how to achieve the highest inspection reliability for security paper, security foil and all applied security elements along with a short ROI, fast setup and easy operation.

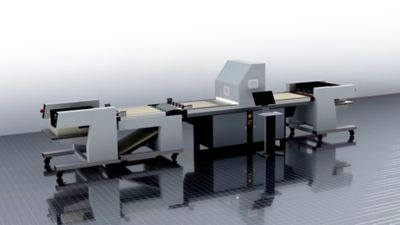

The BankSTAR product line is the only inspection system specifically tailored to the requirements of the security printing and substrates industry. It provides the highest inspection reliability for security paper, security foil and all applied security elements.

Enjoy the confidence of 100% substrate inspection from the global #1 in banknote paper inspection and obtain unsurpassed holography inspection performance, trusted by the leading manufacturers of security threads and diffractive security features.

BankSTAR secures quality by inspecting the surface and security elements of the material. Defects are identified at the earliest possible stage. Productivity is optimized by excluding sub-standard material from further processing. High-end technology components deliver precise and reliable inspection results at any stage within the production process.

But, BankSTAR serves not only as an high-end inspection tool before shipping to your customer, the different systems also help to significantly optimize production efficiency and reduce costs.

BankSTAR in-line inspection systems can also go on a conveyor/sorter platform to make an autonomous stand-alone solution.

Recent additions to our constantly growing BankSTAR solutions portfolio include:

Enhanced Threads Inspection add-on

Finally, there is a solution to what previously had been beyond the scope of in-line automated optical inspection: The Enhanced Threads Inspection add-on for our acclaimed BankSTAR banknote paper inspection verifies the manufacturing quality of embedded and windowed security threads.

Besides the up to 16 checks on security paper thread zones that BankSTAR has been performing anyway, revolutionary new algorithms are now employed to verify the thread décor for defect-freeness, detect thread slitting errors and trace thread fluorescence.

The Enhanced Threads Inspection add-on thereby not only cures a major headache of security paper manufacturers, as security threads cannot be subjected to an incoming inspection before they are inserted into the substrate, but also has the potential of saving paper mills hundreds of thousands of Euro in rejections and wastage due to flawed thread quality.

The Enhanced Threads Inspection add-on makes this quantum leap in banknote paper inspection available to paper makers with just a minor hardware upgrade – mainly, an extra PC for running the additional algorithms – and a quick and easy software update.

Enhanced Threads Inspection is available for BankSTAR Gen4, our latest product generation, and can be deployed at the wet section or dry end of the paper mill, as well as at the cross-cutter.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Low maintenance requirements

- Avoid adding value to waste material

- Defect detection on security paper, security foil and on all applied security elements

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

asdf

asdf

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- 大小

- 1 MB

- 格式

test123

test123

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- 大小

- 403 KB

- 格式

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- 大小

- 2 MB

- 格式

BankSTAR Color: Off-color detection

The detection of off-colors has been an increasing concern of security paper manufacturers. Fluorescent security fibers and extremely low-contrast stains do not differ from the substrate or from one another by grey value, but only by color. Adherence to rigorous quality standards and customer demands therefore requires color evaluation alongside contrast-based inspection.

BankSTAR Color allows the free defintion of color spaces to distinguish between correct colors and off-colors. Unwanted security fibers - visible or UV-reactive - are faithfully detected by dedicated hardware processing in near real-time at even the highest web speeds. Correctly colored security fibers are tolerated. By the same token, oil stains and other off-color contaminations are found even if their grey value is the same as the substrate's.

BankSTAR Color is the perfect companion for BankSTAR WS, PM, OV and CC, adding a one-of-a-kind color feature to security substrate inspection.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Low maintenance requirements

- Avoid adding value to waste material

- Defect detection on security paper, security foil and on all applied security elements

- Features

- Typical defects

- Technical data

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

- Technical data 1

- Technical data 2

- Technical data 3

- Technical data 4

- Technical data 5

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- 大小

- 1 MB

- 格式

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- 大小

- 403 KB

- 格式

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- 大小

- 2 MB

- 格式

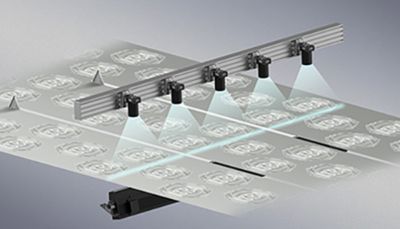

BankSTAR RS: Sheet format inspection

This innovative new inspection solution helps to optimize the trim position of the roll slitter with sheet format inspection.

Incorrectly cut paper rolls lead to significant waste and reduce your throughput – lowering both productivity and yield.

BankSTAR RS ensures exact position control of slitting and trim. It detects even the smallest object positioning deviations and defects.

BankSTAR RS is the only solution for performing format inspection on the roll slitter that helps you avoid waste, increase productivity and gain process control.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Defect detection on security paper, security foil and on all applied security elements

- Low maintenance requirements

- Avoid adding value to waste material

- Inspection at highest processing speeds and real-time classification

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- 大小

- 1 MB

- 格式

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- 大小

- 403 KB

- 格式

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- 大小

- 2 MB

- 格式

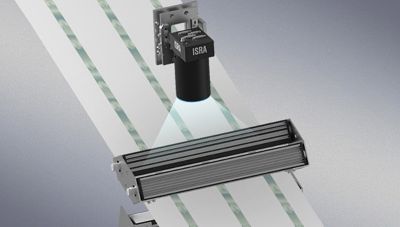

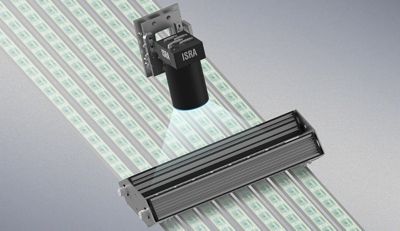

BankSTAR TS: Thread slitting inspection

Automate optical inspection on the thread slitter with a highly specialized thread inspection behind the slitting knife. This new inspection system inspects both the slitting position and the content of the threads on the pancake roll.

The special image-processing algorithm checks each thread separately, tolerating thread oscillation. This enables perfect quality control as each single thread is checked for immaculate quality.

In addition, perfect process control helps re-adjust the knife before the slitting position goes out of tolerance. Reduce quality claims and the associated cost by ensuring that only material meeting your customer´s quality standards is passed along the process chain and shipped.

Benefits

- Low maintenance requirements

- Short ROI, quick setup, easy usability

- Defect detection on security paper, security foil and on all applied security elements

- Avoid adding value to waste material

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- 大小

- 1 MB

- 格式

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- 大小

- 403 KB

- 格式

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- 大小

- 2 MB

- 格式

生产分析-数据驱动高效生产

通过网络生产分析平台,您可以一目了然地查看所有产线的系统状态,或详细分析生产数据。通过质量管理系统,您可以分析历史数据,实时监控当前的检测数据,并确定生产过程的未来趋势。

及早发现生产缺陷

利用实时状态信息和自动报警功能,在生产的每个阶段检测并快速查明违反警戒线的原因。因此,您可以快速解决生产缺陷,缩短停机时间,降低生产成本。

预测性维护

通过分析来自传感器和监控系统的实时数据, 您可以预防潜在的系统故障。这样就可以根据机器的实际状态,而不是遵循固定的时间表,主动制订维护计划。这种数据驱动的方法可以减少停机时间、提高整体生产效率、延长生产线寿命,从而节约成本。

优化生产

通过数据仪表板,您可以在现场或远程比较产线情况和产品数据,为优化提供关键见解。这使您能够在价值链上做出明智的专业决策,从而提高产品质量和盈利能力。您可以持续跟踪优化措施的进度,并通过可视化的高级报告进行展示。

您的收益

- 省时便捷的多产线预览,一个视图显示所有质量相关信息

- 通过监控系统健康数据,最大限度地减少停机时间

- 通过监控质量数据,对质量问题做出更快反应

- 快速消除生产缺陷,降低生产成本

- 改进维护,减少停机时间,提高整体生产率,延长生产线寿命

主要功能

- 生产数据和工厂状态概览

- 从实时数据中获得实时见解

- 基于网络的解决方案,无需安装客户端软件

- 阈值监控和警报

- 面向各部门的仪表盘,可根据客户要求进行调整

- 可集成相关的第三方数据,并将数据导出到客户的系统

量身定制的服务解决方案和个性化培训

为了帮助您的生产系统高效可靠地运行,满足不断增长的市场需求,我们高素质的服务团队为您提供最优的交流和先进的技术分析。我们全球服务网络,快速、可靠。我们可以确保系统的运行、保养、维修以及分析和优化。

此外,您可以在ISRA学院向我们技术过硬的培训师学习,如何让您的员工时刻掌握最新知识,让系统操作员、产品工程师和质量经理成为真正的检测专家。