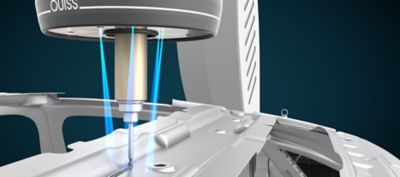

The Bead Inspection Experts – for your quality and productivity

Since 1988, QUISS GmbH has been a reliable partner, specializing in the inspection of all common adhesive and sealant application types and colors. With a focus on precision and quality control, manufacturers are empowered to achieve flawless bead applications and uphold the highest standards of excellence.

2018, QUISS GmbH became a member of the Atlas Copco Group, playing an essential role as the bead inspection expert within the Machine Vision Solution division.

As one of the leading suppliers of bead inspection solutions, expertise and cutting-edge technology from QUISS set the industry standard. QUISS has a distinctive competence in the automotive, regardless of the adhesive or surface type. QUISS systems are deployed by all the world's leading vehicle manufacturers, with thousands of systems running in the adhesive bead inspection application.

QUISS bead inspection solutions are complemented by comprehensive training, service, and support, providing a well-rounded solution for all customers.

Our core competencies:

- Inspection of adhesive and sealant application

- 2D / 3D bead inspection

Products: